What production is complete without pumping equipment, and even more so when it comes to centrifugal pumps. This is one of the most common types, which is used in chemistry, pharmaceuticals, food production and many other industries.

In this article, we will tell you more about Packo Pumps (Belgium), a Belgian manufacturer of pumping equipment that is firmly at the forefront.

History, range and applications

Since 1975, Packo Pumps has been developing and manufacturing stainless steel centrifugal pumps for various industries. Over 300,000 pumps for various applications have been produced since then. The very first pumps were created for the dairy industry, where hygiene is the main criterion for choosing any equipment, which has become a basic principle for Packo Pumps.

Packo Pumps is part of the Fullwood Packo holding. The group has 2 production sites in Belgium, in Zedelgem and Diksmuide. Zedelgem produces milk cooling tanks and components for the food and pharmaceutical industries. The Diksmuide site manufactures industrial pumping equipment and components for milking machines, as well as equipment for transporting and storing milk. The electropolishing department ensures exceptional quality of materials for in-house production and third-party customers.

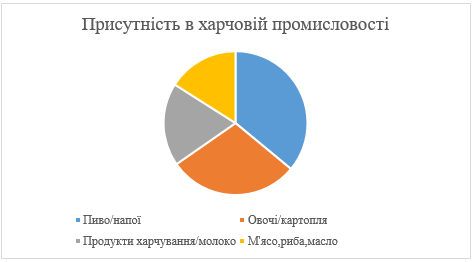

The use of stainless steel and the standard electrochemical surface treatment (electro-polishing) have been the hallmarks of Packo pumps from the outset. This largely determines the main areas of application:

As we can see in the graphs, the main vectors are focused on the food and pharmaceutical industries.

The pump line is presented as follows:

- pumps for general industrial use

- hygienic pumps for the food industry

- hygienic pumps for the pharmaceutical industry

- Individual solutions for specific processes

Individual solutions for specific processes

As mentioned, the first Packo pumps were developed for the dairy industry. The trend and focus on hygienic design continues today.

Selection of construction materials

An important feature is the fact that all Packo pumps are made of stainless steel of at least AISI 316L grade. Some may say that this is a disadvantage and lack of flexibility, but in fact it is simply an emphasis on the main direction of the product line development. As you know, AISI 316L stainless steel is the standard product contact material in food and pharmaceutical production processes.

Surface treatment

The second standard is electropolishing. The Dixmühle production facility has one of the largest stainless steel processing facilities in Northern Europe. The facilities include an electropolishing shop for small and medium-sized components, several pickling and passivation baths for large components, and special equipment for electropolishing the interior of large tanks and containers. All this enables the company to process its own products and provide services to other manufacturers. Electropolishing provides increased corrosion resistance and reduces the risk of harmful microflora accumulating on the working parts of the pump, thereby improving hygiene. Ultimately, the appearance of a polished pump is much more attractive, making the production interior much more aesthetically pleasing.

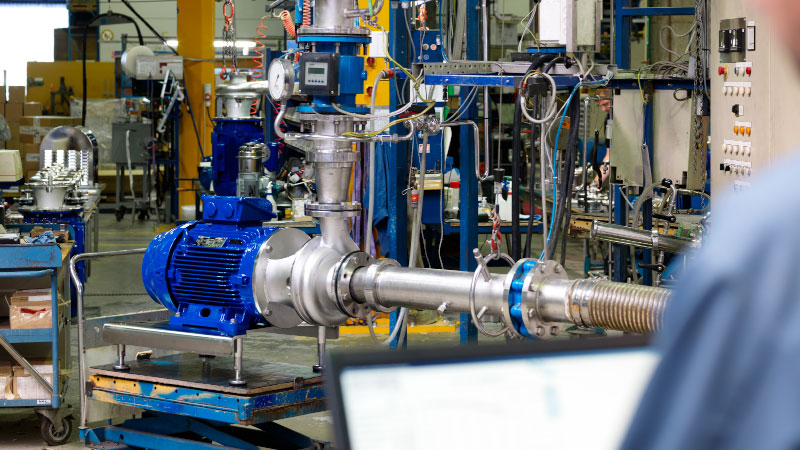

A high-tech product

The Packo pump is a high-tech product created by a team of engineers using specialised software (CFD Computational Fluid Dynamics) and manufactured at the company's production facilities in Belgium. It is important that this production is located in one place, which allows for the most efficient control of the manufacturing process and quality control.

Thanks to state-of-the-art technology and software, each pump model is individually designed and has excellent hydraulic characteristics (high efficiency and cavitation pump NPSH). This in turn ensures low energy consumption and saves you money.

Of course, there are parts that Packo does not manufacture - the electric motor and the mechanical shaft seal. These are among the main elements that are given special attention. As a rule, Packo pumps are equipped with WEG, ABB or Siemens electric motors and Burgmann mechanical seals.

All pumps are tested according to a comprehensive test protocol prior to shipment. Performance, pressure and vibration tests and checks of the main process dimensions are standard for all pumps without exception.

Packo is EHEDG certified for food, pharmaceutical and CIP recirculation pumps.

Packo - a reliable partner and consultant in the selection of pumping equipment

The extensive product range allows you to find the most efficient and optimal solution for your pumping processes. In addition, Packo's experts are always ready for new and interesting challenges and will be happy to develop a customised pump to meet your needs.