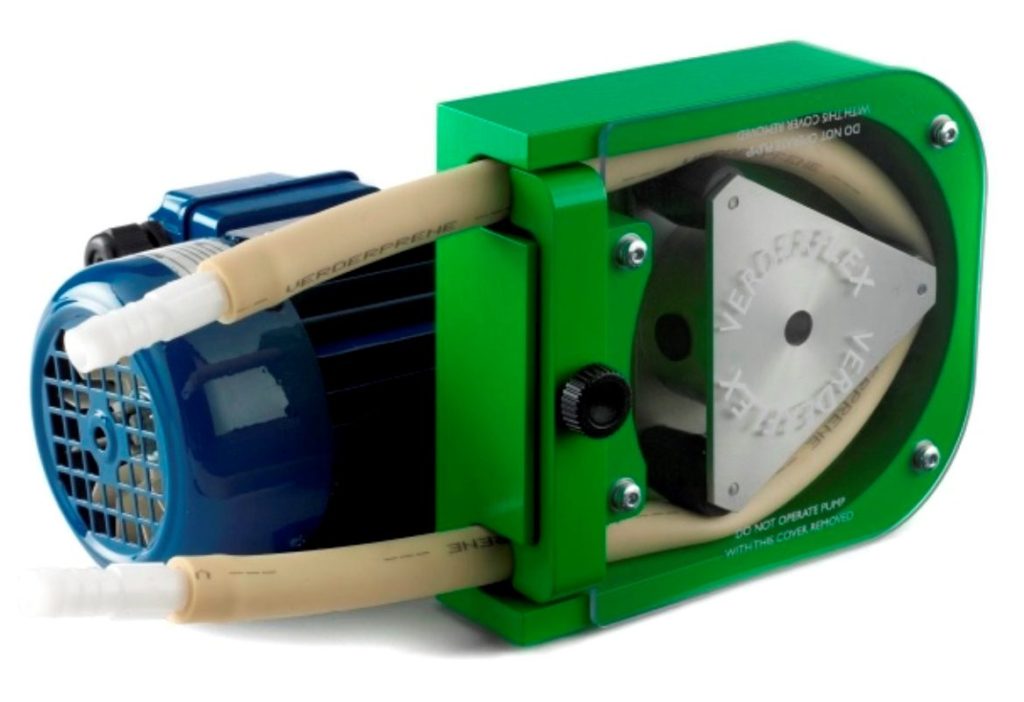

Peristaltic pump (Hose)

Hose pumps (peristaltic pumps) are rotary-volume pumps, this class of pumps is versatile for a wide range of tasks in industrial plants and laboratories. Peristaltic pumps are perfectly suited to modern technological production processes. The basic design of the hose pump ensures gentle pumping of products and allows for the dosing of components.

Peristaltic pump - principle of operation

The principle of operation of peristaltic pumps is very similar to the "peristalsis" of human organs, the principle of which is the contraction and relaxation of muscles in a circular pattern, which in turn ensures the movement of the contents in the system. The flexible tube, which is made of elastomer, is compressed along the entire length of the roller slides, which in turn press the hose, while displacing the liquid inside. Once the hose has returned to its original shape, a vacuum is created, which allows the liquid to flow into the suction port of the peristaltic pump. The deformation of the hose occurs in a smooth sliding motion that does not cause any damage to the product.

In peristaltic pumps, the product does not come into contact with the rollers and is isolated from contaminants, as the product is in contact with the tube only. The product is moved by the rotation of the rotor with the roller shoes mounted on it. The rollers press the tube and push portions of the pumped product through the hose. This ensures that the liquid moves through the tube at a constant speed. Laboratory peristaltic pumps allow for the dosing of a component, as each rotation of the rotor displaces a certain volume, which allows for an accurate measurement of the volume of the product being pumped.

Advantages of peristaltic pumps:

- No lubricant inside the pump casing because there is no friction on the surface of the tube, which increases the service life of the hose;

- Possibility of pumping foodstuffs without the risk of contamination;

- With no lubrication, changing the hose is much easier and cheaper, and there is no need to drain the coolant and no oil or glycerine contamination;

- Capable of pumping products with solid particles, in the form of a slurry, with a size of up to 46% of the hose's internal diameter;

- Suction up to 97% of full vacuum;

- No valves or seals;

- Possibility of CIP treatment;

- Reversible pump operation (reverse flow);