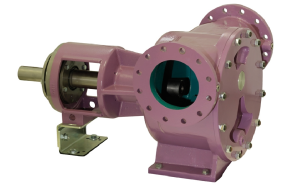

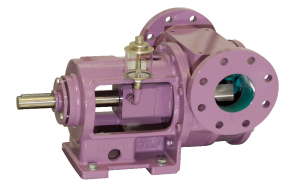

Gear pump

Gear pumps are classified as positive displacement pumps. They are used to pump heterogeneous liquids, including those with a strong abrasive effect, provided that there are no solid particles in the suspension, as well as high-temperature logistics tasks and many other requirements of modern enterprises and industries.

Due to their design, gear pumps ensure good suction capacity, no backflow, and a steady, non-pulsating flow at the pump outlet.

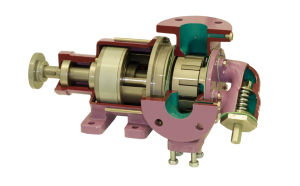

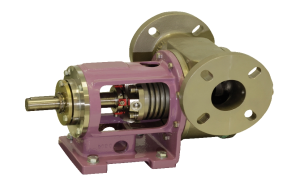

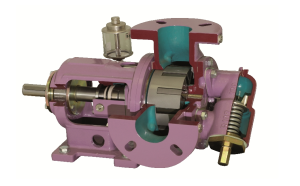

Thanks to its special design, which enables efficient transport of both liquid, clean substances and highly viscous abrasive materials, the gear pump is one of the most versatile types of positive displacement pumps. To ensure its reliable operation, it is necessary to take a responsible approach to the choice of materials and components used in its construction, surface treatment and professional assembly. Careful attention should be paid to the internal gear spacing, which affects the efficiency of performance, pressure, suction and temperature of the product!

These pumps have virtually no wearing parts, so they are designed to operate continuously for a long period of time (several years). The experience of many years in the production and sale of pumps allows us to state that, provided that the pump is selected and installed correctly, it can operate without replacement of parts and the need for additional maintenance for several years.

Technical data for gear pumps:

- The capacity is up to 250 cubic metres per hour;

- Viscosity - up to 1 million cPs;

- The working pressure is up to 16 bar (optionally up to 30 bar);

- The self-priming capacity of a filled pump is up to 6 m;

- Working temperature with media is up to +320 °C;

- The diameter of the connections is from 1″ to 10″.

Advantages ( gear pump )

- Easy to maintain;

- Allows you to reproduce a uniform flow;

- Robust and simple design;

- Long service life and high resistance to breakage;

- Pumping viscosities and liquids;

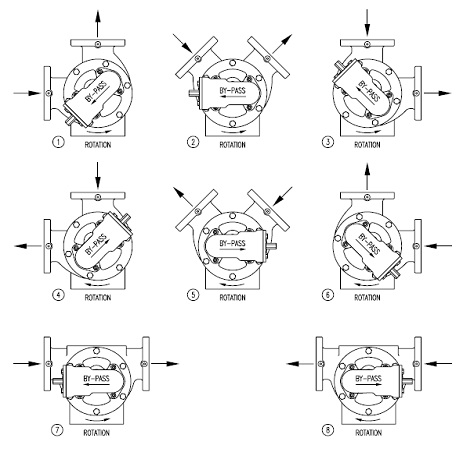

- Reverse action option (excess liquid can be pumped back out without manual intervention);

- It can meet the need for pumping from tens of litres to hundreds of cubic metres of substance per hour.

Gear pumps are used in the chemical industry for pumping:

- colours;

- solvents;

- alcohols;

- varnishes and adhesives;

- isocyanates and polyols;

- oil products and paraffin waxes;

- detergents, synthetic resins;

- formalin;

- of heat carriers.

In the food industry for pumping:

- of chocolate mass;

- cocoa bean oil;

- fats;

- molasses;

- different emulsions;

- palm oil.

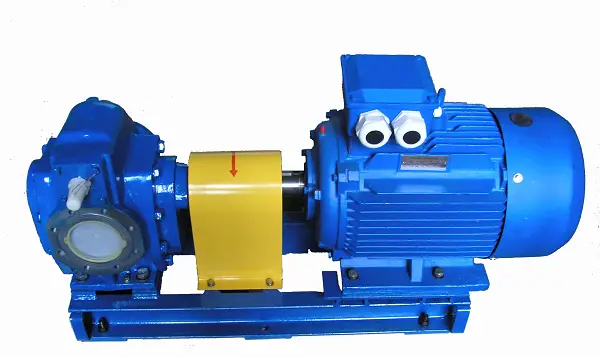

Steiner offers gear pumps in three different versions depending on the application (with R TRM magnetic coupling, for RH+ coolants, for chocolate).

To buy a gear pump, please contact the managers of our company by phone: +38 044 390-7338 or by sending electronic application.