Plastic diaphragm pumps

Design features:

- maximum temperature 120 °C

- maximum pressure 16 bar

- the air mechanism does not require lubrication

- low air consumption

- resistance to abrasion (PE, PE conductive)

Various connection options:

- standard connection - BSP female thread

- PN10, PN16, AISI 316, NPT

- double nozzles

- possibility to rotate the nozzles by 180°

Reliability and durability:

- housings are made of a single piece of polyethylene or PTFE (including conductive versions)

- resistance to chemically aggressive products

- the ability to pump viscous products

Durable membranes (diaphragms):

- smooth work surface

- no central through hole

- no metal parts in contact with the pumped liquid

| DM 15/55 PTS-DM1 | |

|---|---|

| DM - DELLMECO pump 15 - Nominal diameter of pump connections 55 - Maximum capacity (at 8 bar in the air line) | DM1 - OPTIONS: BC1 - Barrier cameras with sensors (NAMUR standard) BC2 - Option BC1 + controller ВС3 - Option BC2 in explosion-proof version (ATEX) DM1 - Membrane rupture detector (NAMUR - ATEX standard) DM2 - Option DM1 + controller SC1 - Stroke sensor, ATEX SC2 - Option CC1 + beat counter SC3 - Option CC2 in explosion-proof version, ATEX SC5 - Pneumatic stroke sensor with electro-pneumatic pressure transducer SC6 - CC5 option + beat counter F1 - PN10 flange connections with EPDM O-rings F2 - PN10 flange connections with NBR O-rings F3 - PN10 flange connections with FEP/FPM O-rings F4 - Flanged pipe connections JIS B2220 F7 - Flange connections for PN10 DIN 2576 pipes F8 - Flange connections for ANSI 150 RF-SO pipes F9 - Flange connections for PN16 DIN 2277/2278 pipes NPT - NPT connection AF1, AF2 - Filter regulator, fittings BF1 - Backflow system, manually operated, with EPDM O-rings BF2 - Backflow system, manually operated, with PTFE O-rings BF4 - Backflow system, manually operated, with EPDM O-rings BF5 - Backflow system, manually operated, with PTFE O-rings D1, D1 - Barrel version NRM, HPS - Version with pressure booster S - Version with double nozzles MV - Version with solenoid air distributor Т - Version on a stainless steel trolley CLEAN - Assembly in a special dust-free room for special pump applications |

| P - Body material: P - Polyethylene R - Conductive polyethylene T- Teflon Z - Conductive Teflon |

|

| T - Membrane material (all conductive): E - EPDM N - NBR T - TFM/PTFE |

|

| S - valve material and shape: C - Ceramic, spherical shape E - EPDM, spherical shape F - Teflon, cylindrical shape N - NBR, spherical shape P - Polyethylene, cylindrical shape T - Teflon, spherical shape U - Polyurethane, spherical shape |

|

| MEMBRANES (DIAPHRAGMS) | OPERATING TEMPERATURE MIN MAX | PARTS IN CONTACT WITH THE PRODUCT |

|---|---|---|

| NBR: Oil and petrol resistant rubber. Good resistance to solvents, lubricants, water, oils. Not suitable for highly polar solvents (acetone, etc.), ozone, chlorinated hydrocarbons and nitrocarbons. | -30°C +90°C | PE (polyethylene) is very strong and extremely resistant to abrasion. The moisture absorption capacity is very low. Good chemical resistance to major chemicals. Only strong oxidants such as nitric acid, sulphuric acid and halogens can damage PE. PE is a competitor to PP (polypropylene), which is often used in the production of pumps. The temperature and chemical parameters of these two materials are believed to be similar. However, the overall similarity of the mechanical properties of these materials is limited: tests based on the interaction of these materials with water and sand have shown that the abrasion resistance of RE is 7 times higher than that of PP and 1.6 times higher than that of steel. RE is also more resistant than, for example, cast iron or aluminium. This high resistance plays an important role in many applications (electroplating baths, printing inks, lime milk, grinders and glazes in the ceramic industry). PTFE is a thermoplastic polymer or tetrafluoroethylene. It has a smooth surface and a very low coefficient of friction. It is physiologically harmless, can be used at high temperatures and has almost universal resistance to chemically aggressive environments. However, it is not very resistant to abrasion and becomes brittle at low temperatures. |

| EPDM: Ethylene propylene diene rubber. Very good chemical resistance. Not suitable for oils and solvents. Resistant to ketones and alcohols. | -40°C +120°C | |

| PTFE: Polytetrafluoroethylene, fluoroplastic. One of the most chemically resistant materials. There are very few substances to which it is not resistant: alkali metals, gaseous fluorine and some fluorinated chemicals such as chlorotrifluoride or oxygen difluoride, which release free fluorine with increasing temperature. | -37°C +120°C |

Polyethylene (PE) and PTFE pumps

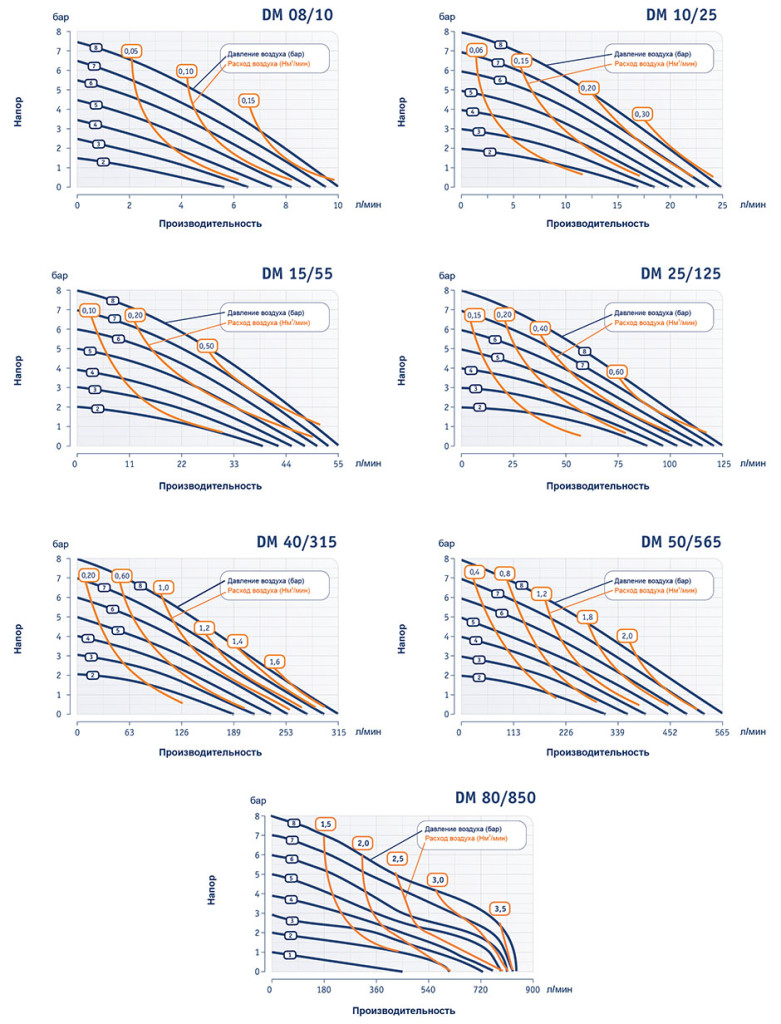

| 08/10 | 10/25 | 15/55 | 25/125 | 40/315 | 50/565 | 80/850 | |

|---|---|---|---|---|---|---|---|

| Max. capacity, l/minv | 10 | 25 | 55 | 125 | 315 | 565 | 800 |

| Max. pressure, bar | 8 | ||||||

| Size of pipe connections | 1/4" | 3/8" | 1/2" | 1" | 1 1/2" | 2" | 3" |

| Compressed air connection size | R 1/8" | R 1/8" | R 1/4" | R 1/4" | R 1/2" | R 1/2" | R 3/4" |

| Dry suction height m.in.s. | 0.5/1.5* | 2.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 |

| Suction height under the bay, m.in.s. | 9 | ||||||

| Max. diameter of solid particles, mm | 2 | 3 | 4 | 7 | 10 | 12 | 15 |

| Max. operating temperature - PE, °C | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Max. operating temperature - PTFE, °C | 110 | 110 | 120 | 120 | 120 | 120 | 120 |

| Weight - PE, kg | 0.9 | 1.4 | 5 | 9 | 23 | 42 | 170 |

| Weight - PTFE, kg | 1.4 | 2.4 | 7 | 16 | 43 | 87 | - |

| Housing material | PE, PTFE | PE | |||||

| Material of membranes (diaphragms) | TFM/PTFE | NBR, EPDM or TFM/PTFE | |||||

| Ball valve material | PTFE, AISI 316 | NBR, EPDM, PTFE, AISI 316, PU | NBR, EPDM, PTFE | ||||

| Material of cylindrical valves | PTFE | PE or PTFE | - | ||||

| Material of the sealing rings | NBR, EPDM, FEP/FPM, PTFE+EPDM or PTFE+FPM | ||||||

| * 0.5 m for ball valves and 1.5 m for cylindrical valves | |||||||

| A | B | C | D | E | F | G | H | I | ØJ | pumps | L | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DM 08/10 | 70 | 113 | 120 | 15 | G 1/4" | 58 | R 1/8" | 107 | 10 | 15 | 50 | 86 |

| DM 10/25 | 105 | 128 | 164 | 18 | G 3/8" | 84 | R 1/8 | 150 | 10 | 15 | 75 | 93 |

| DM 15/55 | 153 | 177 | 235 | 25 | G 1/2" | 87 | R 1/4" | 217 | 18 | 30 | 112 | 136 |

| DM 25/125 | 200 | 232 | 312 | 35 | G 1" | 123 | R 1/4" | 287 | 28 | 40 | 140 | 170 |

| DM 40/315 | 270 | 312 | 426 | 42 | G 1 1/2" | 109 | R 1/2" | 388 | 30 | 60 | 190 | 227 |

| DM 50/565 | 350 | 385 | 540 | 45 | G 2" | 158 | R 1/2" | 485 | 30 | 60 | 270 | 282 |

| DM 80/850 | 480 | 580 | 800 | 100 | G 3" | 388 | R 3/4" | 690 | 40 | 75 | 395 | 495 |

Pumps made of polyethylene (PE) and fluoroplastic (PTFE) ATEX flameproof version

The use of conductive PE and PTFE in the production of plastic pumps makes it possible to ground non-metallic pumps. This feature makes it possible to safely use these pumps for pumping solvents, alcohols and other flammable and explosive products without the risk of sparks from static electricity. This feature also applies to pumps made of aluminium, cast iron and stainless steel.

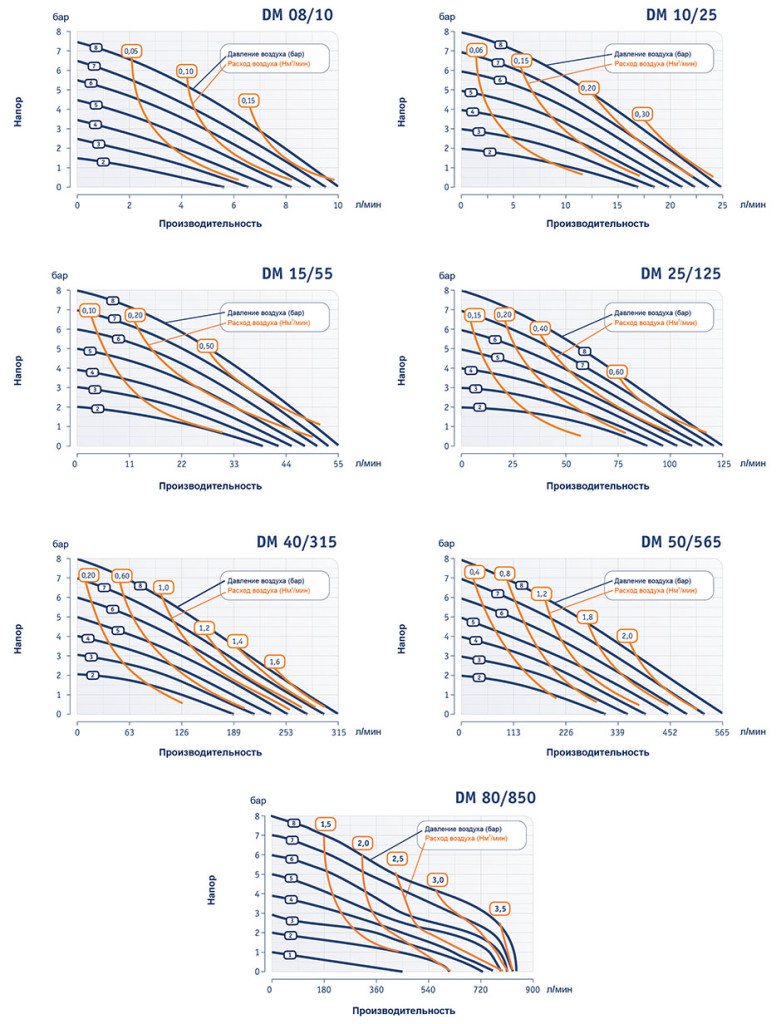

| 08/10 | 10/25 | 15/55 | 25/125 | 40/315 | 50/565 | 80/850 | |

|---|---|---|---|---|---|---|---|

| Max. capacity, l/minv | 10 | 25 | 55 | 125 | 315 | 565 | 800 |

| Max. pressure, bar | 8 | ||||||

| Size of pipe connections | 1/4" | 3/8" | 1/2" | 1" | 1 1/2" | 2" | 3" |

| Compressed air connection size | R 1/8" | R 1/8" | R 1/4" | R 1/4" | R 1/2" | R 1/2" | R 3/4" |

| Dry suction height m.in.s. | 0.5/1.5* | 2.0 | 3.0 | 4.0 | 4.0 | 5.0 | 5.0 |

| Suction height under the bay, m.in.s. | 9 | ||||||

| Max. diameter of solid particles, mm | 2 | 3 | 4 | 7 | 10 | 12 | 15 |

| Max. operating temperature - PE, °C | 70 | 70 | 70 | 70 | 70 | 70 | 70 |

| Max. operating temperature - PTFE, °C | 110 | 110 | 120 | 120 | 120 | 120 | 120 |

| Weight - PE, kg | 0.9 | 1.4 | 5 | 9 | 23 | 42 | 170 |

| Weight - PTFE, kg | 1.4 | 2.4 | 7 | 16 | 43 | 87 | - |

| Housing material | PE, PTFE conductive | PE conductive | |||||

| Material of membranes (diaphragms) | TFM/PTFE | NBR, EPDM or TFM/PTFE | |||||

| Ball valve material | PTFE, AISI 316 | NBR, EPDM, PTFE, AISI 316, PU | NBR, EPDM, PTFE | ||||

| Material of cylindrical valves | PTFE | PE or PTFE | - | ||||

| Material of the sealing rings | NBR, EPDM, FEP/FPM, PTFE+EPDM or PTFE+FPM | ||||||

| * 0.5 m for ball valves and 1.5 m for cylindrical valves | |||||||

| A | B | C | D | E | F | G | H | I | ØJ | pumps | L | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DM 08/10 | 70 | 113 | 120 | 15 | G 1/4" | 58 | R 1/8" | 107 | 10 | 15 | 50 | 86 |

| DM 10/25 | 105 | 128 | 164 | 18 | G 3/8" | 84 | R 1/8 | 150 | 10 | 15 | 75 | 93 |

| DM 15/55 | 153 | 177 | 235 | 25 | G 1/2" | 87 | R 1/4" | 217 | 18 | 30 | 112 | 136 |

| DM 25/125 | 200 | 232 | 312 | 35 | G 1" | 123 | R 1/4" | 287 | 28 | 40 | 140 | 170 |

| DM 40/315 | 270 | 312 | 426 | 42 | G 1 1/2" | 109 | R 1/2" | 388 | 30 | 60 | 190 | 227 |

| DM 50/565 | 350 | 385 | 540 | 45 | G 2" | 158 | R 1/2" | 485 | 30 | 60 | 270 | 282 |

| DM 80/850 | 480 | 580 | 800 | 100 | G 3" | 388 | R 3/4" | 690 | 40 | 75 | 395 | 495 |