Maxiprime barrel pumping system

Maxiprime barrel pumping systems for pastes and non-flowing and highly viscous liquids.

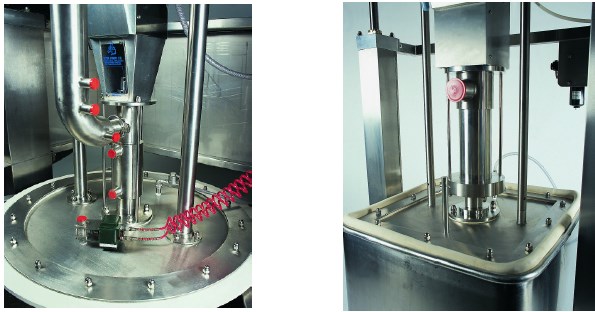

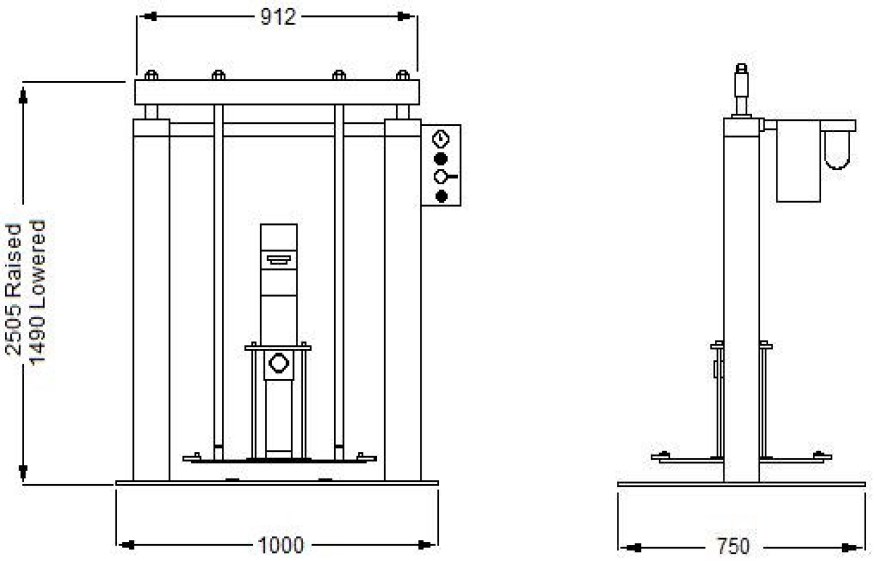

Pumping a large volume of non-flowing, highly viscous products from one container to another is a challenging task. When selecting a pump, it is necessary to take into account not only the density of the pumped liquid, but also the losses that will necessarily be present during operation. In solving this problem, our engineers found a way out of the situation - the use of the Kecol Maxiprime system with a two-cylinder clamping device based on a shortened Kecol piston pump, ensuring the absence of cavitation. As soon as the product level drops, the sides of the container are cleaned by the system's pressure plate.

Main advantages:

- Pumping highly viscous, non-fluid products up to 10,000 Poise

- Elimination of product residues

- Simple and safe operation of the structure

- Polished stainless steel or painted steel construction

Areas of application:

Food industry: honey, sauces, margarine, oil, fruit and vegetable concentrates, etc.

Pharmaceutical industry: ointments, lanolin, aluminium hydroxide, pastes, petroleum jelly, etc.

Chemical industry: adhesives, paints, mastics, lubricants, paints, resins, tile adhesive, sealants, waxes, putties, etc.

Principle of work:

The compressed air enters both cylinders simultaneously, transmitting the downward force to the clamping device, which in turn creates an overpressure in the container, allowing the product to be forced directly into the pump's air intake. The additional pressure on the product surface created by the Maxiprime system enables the Kecol piston pump to pump cold liquids with very high viscosities. During the cycle, the product level gradually drops and the scraper of the clamping device wipes the sides of the container. As soon as the container is empty, the direction of the air cylinders reverses to lift the pump and clamp in preparation for a container change.

Measuring cylinders used in conjunction with a Kecol piston pump distribute a given volume of liquid or viscous product. They are made of either carbon steel or 316 stainless steel and are available with manual or pneumatic drive and fixed or adjustable outputs from 200 ml to 3 litres.

The variable displacement pump provides a means of varying the stroke length and therefore the output of a Kecol pump. When used in conjunction with a piston stroke counter, the variable displacement pump will deliver a set volume of viscous product and stop when the set number of strokes is reached.

In situations where product temperature needs to be maintained, Kecol pumps can be equipped with a water jacket, that allows hot or cold water to circulate through the entire length of the pump.

The Megaprime twin-cylinder clamping system, based on the Maxiprime system, is suitable for containers up to 1200 mm in diameter and can be adapted to square hoppers.

If your requirement does not fit within the standard pump parameters or systems, Kecol is ready to design and manufacture a unit to meet your requirements. Our engineers are always happy to discuss the many options for upgrading or complicating the system.