В’язкість рідин: що потрібно знати перед вибором насоса

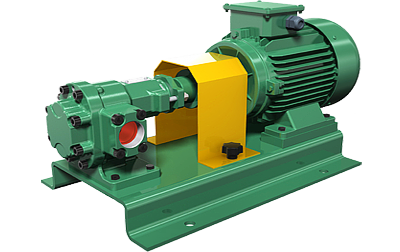

«У нас в’язка рідина — значить, потрібен об’ємний насос: гвинтовий, шестеренний, перистальтичний, мембранний…». Таку відповідь часто можна почути від замовника, який робить підбір обладнання інтуїтивно. Але при роботі з в’язкими середовищами нюансів значно більше, ніж здається на перший погляд. Саме тому тему в’язкості варто розглянути глибше.

Що таке в’язкість і як вона впливає на роботу насоса

В’язкість — це характеристика, що визначає плинність рідини. Високов’язкі середовища (мед, крем, згущене молоко) течуть повільно, низьков’язкі — швидко. Фактично це прояв внутрішнього тертя, яке зменшується при нагріванні та збільшується при зниженні температури.

Під час підбору насоса важливо врахувати:

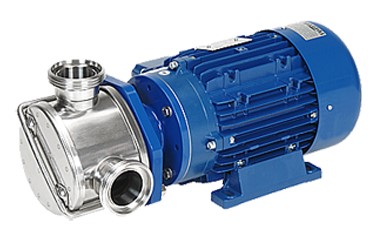

- в’язкі продукти — це все, що не впорається з відцентровим насосом (200+ cSt);

- кожен тип насоса має свої межі по в’язкості та коефіцієнти втрат;

- деякі продукти не мають плинності зовсім (наприклад, фарш), але їх теж можна перекачувати;

- хімічний склад рідини визначає матеріал проточної частини;

- в’язкі середовища часто густішають під час охолодження та мають підвищену щільність.

Типи в’язких рідин та їх поведінка

1. Ньютонівські рідини

Поведінка не змінюється при зміні швидкості руху.

Приклад: вода, спирт, розчинники.

2. Дилатантні рідини (згущуються при зсуві)

Чим швидше вони рухаються, тим в’язкішими стають.

Приклад: вершки, масло після збивання.

Їх не можна перекачувати відцентровими насосами.

3. Пластичні рідини (мають межу плинності)

Поки точку зрушення не подолано — рідина стоїть.

Приклад: кетчуп, майонез.

4. Тиксотропні рідини (стають рідшими при перемішуванні)

Густі у спокої, рідкі під час руху.

Приклад: фарби, клеї, гелі, мастила.

Кінематична та динамічна в’язкість

Для насосів важлива кінематична в’язкість, яку вимірюють у сантистоксах (cSt):

- вода за 20 °C = 1 cSt

- моторна олива = 500+ cSt

В’язкість визначає опір руху в трубах, а густина — вагу продукту, що прямо впливає на потрібний натиск.

Приклад: перекачування згущеного молока

Постановка задачі:

6000 cSt, 5 м³/год, 2 бар, труба 50 мм.

Насос підібрано правильно, але часто не враховують втрати у трубопроводі.

30 метрів полімерної труби без вигинів дають:

➡ понад 16 бар втрат тільки на шорсткість стінок!

Отже, потрібен насос значно дорожчий і потужніший.

Як зменшити втрати?

- труба 100 мм → втрата ≈ 1 бар

- труба 75 мм → ≈ 3 бар

Різниця у вартості насоса та експлуатації — колосальна.

Висновки

- Універсальних насосів для в’язких рідин не існує.

- Потрібно враховувати в’язкість, тип рідини, густину, температуру, довжину та діаметр трубопроводу, матеріали, втрати на шорсткість.

- Правильний вибір насоса дозволяє уникнути перевитрат електроенергії і дорогих аварій.

Фахівці Steiner підберуть насос для будь-якого типу в’язких продуктів.

📞 +380 44 390 73 38