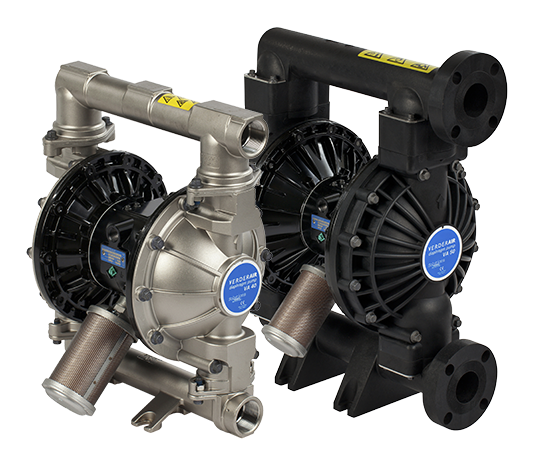

Viscous, aggressive, flammable, abrasive and vibration-sensitive liquids can be pumped with explosion-proof diaphragm pumps.

Other pumping equipment is not always able to cope with such tasks and is вmore expensive. This is due to both the principle of suction and the characteristics of this mechanism, including the risk of sparks and the sensitivity of construction materials to chemically active substances.

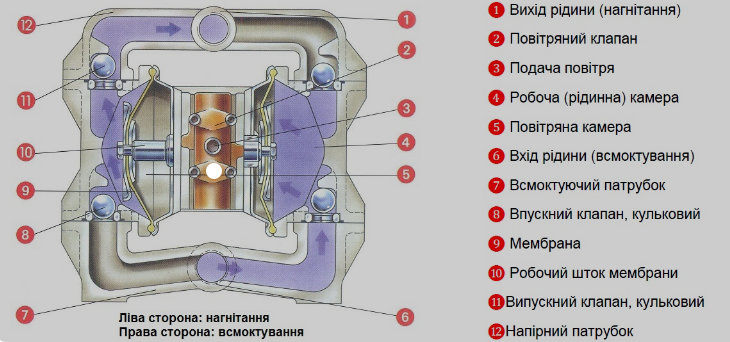

The principle of operation of diaphragm pumps is to move the working fluid through a flexible diaphragm. The main stages of diaphragm pump operation are as follows:

Suction: At the beginning of the cycle, the diaphragm is in a position where the pump inlet chamber is open and the outlet chamber is closed. As the diaphragm contracts, external pressure compresses the inlet chamber, creating a negative pressure that forces the process fluid through the inlet valve into the pump chamber.

High-pressure stroke: After suction, the diaphragm moves to the compressed position, clamping the inlet valve and blocking the flow of process fluid from the inlet chamber. The temporary outlet valve opens, allowing the process fluid to flow out through the outlet chamber.

The outlet valve closes: Once the diaphragm reaches its maximum compression, the outlet valve closes, blocking the path to the outlet chamber.

Relaxation of the membrane: The diaphragm relaxes, returning to its original position. This creates a negative pressure in the outlet chamber, which forces the process fluid through the outlet valve and out of the pump.

This cycle is repeated continuously, ensuring that the working fluid is constantly moving through the pump.

Diaphragm pumps compared to other pumping equipment

Pumps with different operating principles are used for each process that is pumped with liquid media, but each is designed to solve a specific task with severe limitations.

- Centrifugal pumps do not work with viscous liquids and destroy the structure of agitation-sensitive liquids, and dry running is not allowed.

- Cam, gear and screw types must not be used for liquids contaminated with solid particles and for dry running.

- Dry suction is not possible with almost any type of pump, except for gear pumps, peristaltic pumps and centrifugal pumps with a special design, but even these have serious limitations.

- All types of these pumps are not allowed to operate in explosive atmospheres. Pneumatic pumps, on the other hand, have an explosion-proof design.

Diaphragm pneumatic pumps do not have these disadvantages. In addition, they do not have an electric motor and other electrical components, which allows them to be used in a submersible state.

In contrast to other types of pumping units, pneumatic diaphragm pumps are not driven by an electric motor, but rather by a pneumatic actuator. The energy of an air stream with a pressure of up to 8 bar drives the pneumatic actuator, which makes the diaphragm pump diaphragms work, pumping water or other liquids regardless of their viscosity, contamination, chemical activity or the presence of bubbles.

The use of chemically resistant polymers (PP, PVDF, PTFE, PE, POM, etc.) as well as corrosion-resistant aluminium and stainless steel alloys allows the use of diaphragm pumps for pumping:

- acids and alkalis;

- oil products, including viscous fuels and lubricants;

- varnishes and paints, including solvents for them;

- food, fats and beverages;

- cosmetics;

- pharmacological substances;

- of paper pulp.

The applications for which a diaphragm pump can be used:

- Diaphragm pumps are used to pump liquids that may contain solid particles or viscous substances that cannot be pumped by conventional pumps.

- They can be operated in self-priming mode, which means that they are able to lift liquid from the lower reservoir without an external auxiliary pump.

- Diaphragm pumps can be electrically, pneumatically or hydraulically driven, depending on the energy source used to move the diaphragm.

- They can be equipped with one or more diaphragms, depending on the fluid flow rate and pump capacity.

- Diaphragms in pumps can be made of different materials such as rubber, Teflon, stainless steel or polyethylene, depending on the characteristics of the fluid being pumped.

- They are able to operate in a wide range of temperatures and pressures, including extreme conditions.

- Diaphragm pumps are often used in water supply systems, water treatment, the automotive industry, pharmaceuticals, the chemical industry and many other industries.

- They are compact, lightweight and have a simple design that makes them easy to install and maintain.

- Diaphragm pumps are highly reliable and have a long service life due to the absence of wearing parts and the simplicity of the operating mechanism.

- They can be used for a variety of applications, including pumping liquids, dosing, draining, vacuum evacuation and other fluid movement operations.