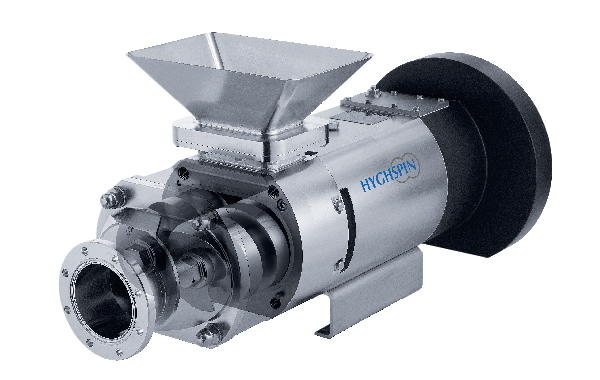

Jung HYGHSPIN Hopper twin screw pump

It is an effective solution for pumping non-fluid products.

Hygienic design, high efficiency, gentle pumping.

The Jung HYGHSPIN Hopper twin screw pump is a continuation of the globally proven HYGHSPIN series made of stainless steel. The innovative twin screw pump with funnel opening can easily convey products with viscosities of up to 1000 Pa. Its conveyor screws are elongated so that they can suck in non-fluidic products below the inlet funnel like an extruder and then feed them into the pump chamber. The absence of an external extruder ensures particularly gentle handling.

The Jung HYGHSPIN Hopper twin screw pumps combine a unique 3-in-1 solution: feeding, transport and cleaning in one component. It is available in a block design or with a free shaft end.

The Jung HYGHSPIN Hopper pump is available in sizes 70, 90 and 125. The maximum conveying speed is around 20 m³/h. In the standard version, the pressure drop is a maximum of 10 bar. On request, up to 25 bar is possible.

Advantages:

- Self-contained design (use of extended feed screws with extrusion function and extended inlet)

- Gentle pumping for sensitive solids (product is pumped into the pump chamber by gravity)

- Partially suitable for boiling media (minimises inlet losses, provides maximum protection against cracks)

- Significant cost savings (reduced investment and maintenance costs)

- Higher quality (pump made entirely of stainless steel)

- Easy to maintain (no need to remove the pump from the system for maintenance and repair work)

- High flexibility (products of different viscosities and volumes can be pumped with one pump)

- Gentle pumping (low speed, minimal pulsation, no pressure effects)

- Highest level of hygiene (no cavities and excellent rinsing of shaft seals)

- Adaptation to CIP and SIP cleaning (system cleaning and sterilisation, use as a CIP pump).