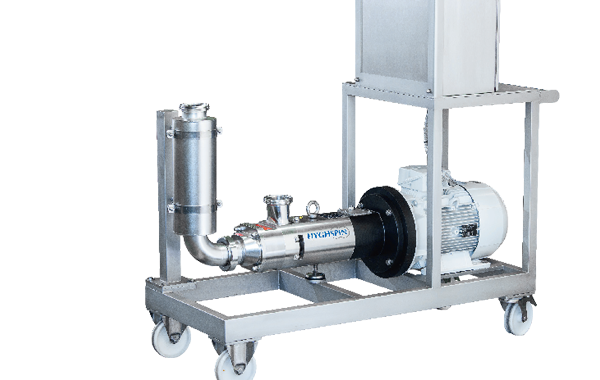

Twin screw pumps are positive displacement pumps and are designed to deliver stable pressure and high self-priming. Twin screw pumps have a very high level of reliability and a long service life. They are an excellent choice for solving a wide range of tasks at any enterprise or production facility, regardless of the complexity of the workflow or the product being pumped.

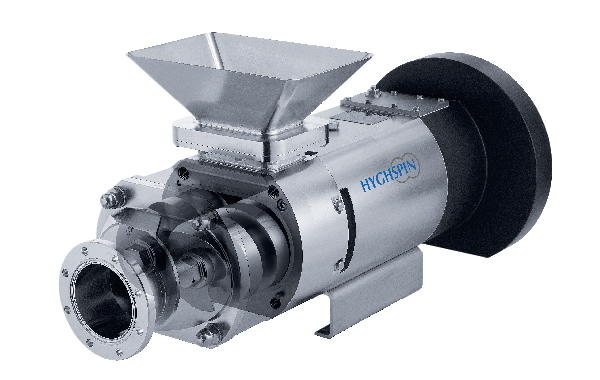

Twin screw pumps - design features

A twin screw pump is a positive displacement pump with automatic priming function and external gearing and bearings. These pumps are available in a wide range of models and in various designs. The layout of the double screw pump is based on longitudinal balancing of all rotating elements. The metal components of the pump work without contact and collision.

The twin screw pumps can handle a wide variety of process fluids and products: bitumen, molasses, seawater, caustic and known solutions, hydrocarbons with different viscosities, oily products, high viscosity liquids, abrasives. All Jung Process Systems pumps are manufactured in accordance with international certificates EHEDG, 3-A (USA) and Atex.

Twin screw pumps are used for pumping viscous, abrasive and aggressive liquids in the food, chemical and oil industries.

They provide stable, pulsation-free flow, high efficiency and reliability even in difficult conditions.

The choice of pump depends on the type of fluid, temperature, pressure and technological requirements. Our experts will help you select the optimal equipment.

Yes, Steiner offers original twin-screw pumps with an official warranty and delivery throughout Ukraine.

Yes, we provide full service, repair and supply of original spare parts for twin screw pumps.