Бочкові насоси (drum pumps) не завжди на виду, але саме вони часто рятують ситуацію там, де потрібно акуратно, безпечно й контрольовано перекачати рідину з бочки, єврокуба чи невеликої цистерни.

Що таке бочковий насос і для чого він потрібен?

Як випливає з назви, бочкові насоси призначені для перекачування рідких середовищ з тарних ємностей:

- стандартних металевих та пластикових бочок

- IBC-контейнерів (єврокубів)

- невеликих резервуарів і цистерн

Вони можуть працювати в різних режимах:

- фасування (дозоване заповнення тари)

- повне спорожнення ємностей

- перекачування на відстань по горизонталі та/або вертикалі

За конструкцією бочкові насоси належать до напівзанурених: робоча частина опускається в ємність, двигун залишається зовні. Фактично, це «мала версія» вертикальних відцентрових або інших типів насосів, адаптована саме під роботу з бочками та контейнерами.

Переваги бочкових насосів

До ключових сильних сторін бочкових насосів можна віднести:

- Сумісність з більшістю стандартних контейнерів

Одна помпа може працювати з різними типами бочок та єврокубів за рахунок стандартних довжин занурювальної частини. - Мінімальний залишок продукту

Конструкція дозволяє майже повністю спорожнити ємність, зменшуючи втрати дорогих реагентів або продукту. - Контрольований потік і дозування

Насоси підходять не лише для простого перекачування, а й для відносно точного прокачування та фасування. - Простота монтажу та обслуговування

Насос легко встановити, зняти, промити; конструкція, як правило, не вимагає складного сервісу. - Можливість перекачування на відстань

За правильно підібраних параметрів бочковий насос забезпечує стабільну подачу рідини на необхідну відстань. - Регулювання продуктивності

Потік можна регулювати за рахунок частотного перетворювача, дроселювання чи використання моделей з різними характеристиками.

Обмеження та недоліки

Водночас бочкові насоси мають низку технічних обмежень, які варто враховувати на етапі вибору:

- Обмеження за в’язкістю та густиною рідини

Для сильно в’язких продуктів (важкі мастила, пасти, густі сиропи) стандартний бочковий насос може бути неефективним — потрібні спеціалізовані рішення. - Не призначені для високих напорів і великих витрат

Це рішення для локальних задач, а не для побудови магістральних насосних станцій чи високонапірних систем.

Fields of application

Бочкові насоси використовуються там, де потрібно безпечно та акуратно працювати з рідинами в тарі:

- The chemical industry

Перекачування хімреагентів, кислот, лугів, агресивних середовищ з бочок та єврокубів, спорожнення невеликих резервуарів у лабораторіях та цехах. - Food industry

Переміщення сиропів, концентратів, інгредієнтів, допоміжних рідин, що використовуються у виробництві продуктів. - Фармацевтика та косметика

Робота з компонентами, які постачаються в бочках, де важливі чистота процесу, безпека та мінімізація контакту оператора з продуктом. - Загальнопромислові задачі

Злив/налив технічних рідин, олив, мийних засобів, емульсій тощо.

Типова конструкція бочкового насоса

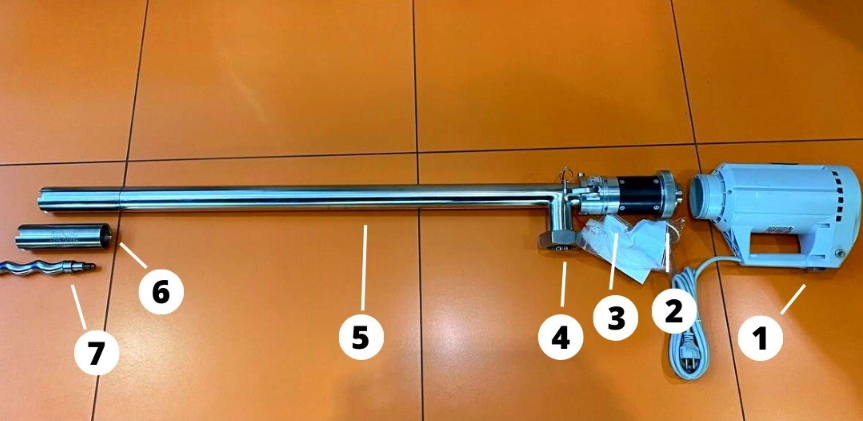

На основі представленого на фото варіанта можна виділити основні вузли:

- electric motor

- camera mounting nut

- камера (корпус)

- вихідний патрубок із накидною гайкою

- робоча камера / гідравлічна частина

- stator

- rotor

Конструкція може відрізнятися залежно від виробника та принципу роботи (відцентровий, шестеренний, пневматичний тощо), але загальна логіка — занурювана помпа з зовнішнім приводом — зберігається.

Якщо вам потрібно купити бочковий насос з оптимальним співвідношенням ціна/функціональність і правильно підібрати модель під конкретну рідину та завдання, звертайтеся до менеджерів нашої компанії за телефоном:

+38 044 390-73-38.