LB series rubber lobe vane pump

The field of application of cam pumps:

1.Water treatment:

- Sludge;

- Mule;

- Clay mortar;

- Wastewater;

- Sea water;

- Oil spill;

- Organic fertiliser, etc.

2.Chemical industry:

- Detergents;

- Glycerin;

- PAR;

- Glue;

- Paints;

- Fuel oil;

- Slicker, etc.

3.Food industry:

- Wine;

- Vegetable and olive oils;

- Patoka;

- Glucose;

- Chocolate, etc.

General characteristics

The main characteristics of cam-type rotary vane pumps are as follows:

- Self-priming;

- Reversible;

- The capacity is 120 m3/hour;

- The working pressure is up to 8 bar;

- Suitable for environments up to 100,000

- With viscosity;

- The maximum permissible size for solid inclusions is 50 mm;

- Resistant to abrasive environments.

Standard options

Standard options for this type of pump include:

- They have a reverse bypass valve;

- Rotors can be rubberised or metal;

- The presence of a pressure safety valve;

- Made of stainless steel;

- They are equipped with a screw drive;

- Fittings can be: industrial, sanitary, quick-release.

Types of pumps

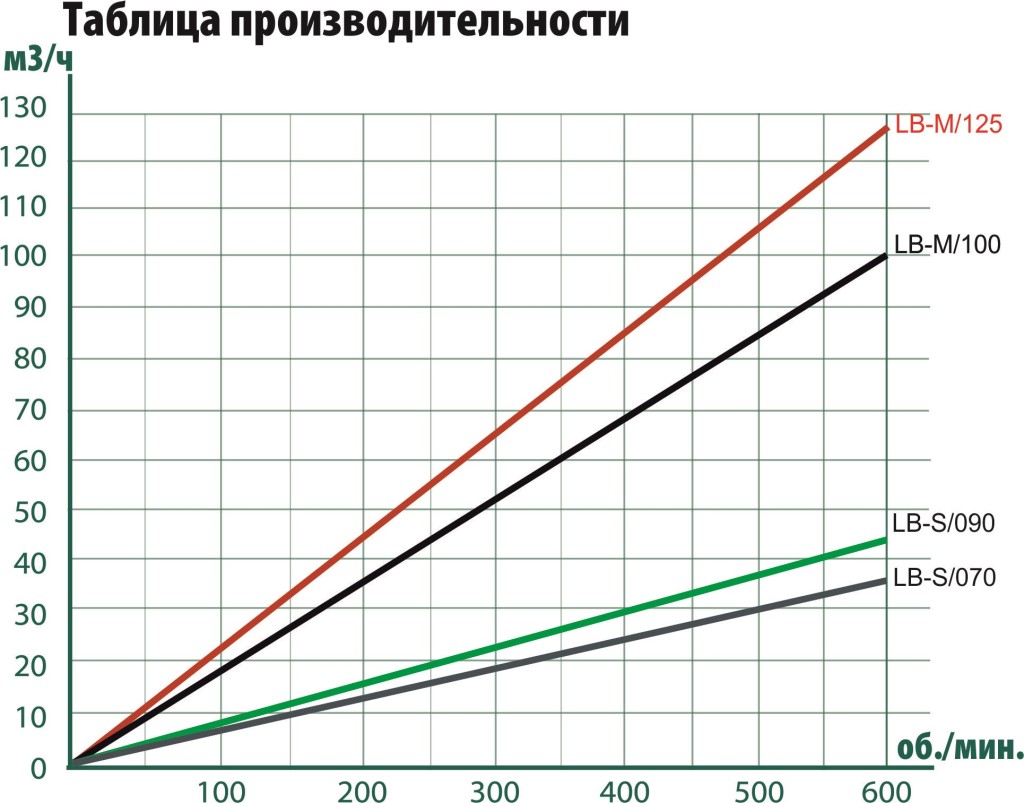

We offer the following types of cam-operated rotary vane pumps:

- LB-S/70;

- LB-S/90;

- LB-М/100;

- LB-М/125.

This pump effectively pumps viscous and abrasive liquids thanks to rubber blades that provide reliable sealing.

LB series pumps are used in the food, chemical and pharmaceutical industries for the gentle and safe transport of liquids.

They ensure smooth pump operation, reduce product damage and have high wear resistance.

It is necessary to consider the type of liquid, viscosity, temperature, and pumping volumes. Our specialists will assist you with the selection.

Steiner offers original LB series rubber vane pumps with an official warranty and delivery throughout Ukraine.