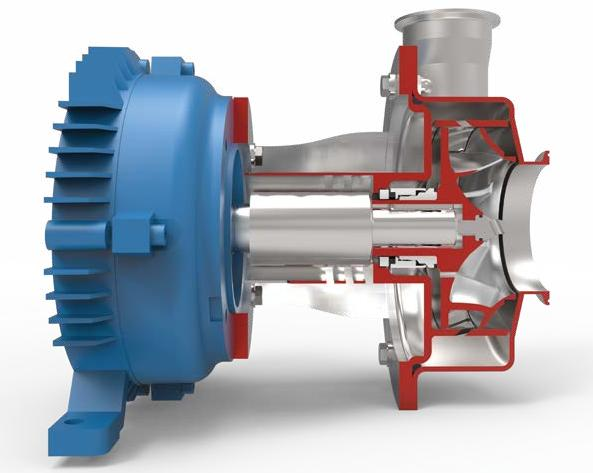

For processes that require not only mixing, but also pumping at a given pressure, the Belgian brand Packo offers a technical solution in the form of mixer pumps, represented by the FP2 series with an open impeller and the FP3 series with a closed impeller. Since 1975, Packo Pumps has been developing and manufacturing stainless steel centrifugal pumps for various industries

Mixer pumps are used for inline mixing, homogenising and dispersing of products. The shear torque is generated between the rotor and the stator, which has an innovative design patented by the manufacturer. The amount of shear can be increased by increasing the rotational speed and can reach 100,000 s-1 at 3600 rpm. The use of such mixing pumps is advisable when the goal is to obtain a homogeneous solution of two liquids with a large difference in viscosity or density and to break up the particles to obtain an emulsion and pump the product at the same time.

Thanks to modern technologies and software, each pump model is individually designed and has excellent hydraulic characteristics (high efficiency and cavitation reserve of the pump NPSH).

The advantages of Packo mixer pumps include the following:

- Electropolishing, monoblock design, easy installation and maintenance

- Several seal diameters are available - SFP2: Ø 33 mm - SFP3: Ø 43 mm

- Availability of ATEX certificate

- Easy cleaning (CIP and SIP)

- Good self-priming

- High mechanical and hydraulic shear

- High energy efficiency