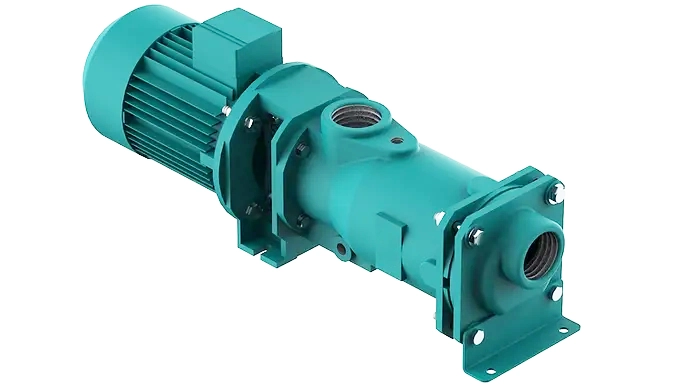

Screw pump - FM series

The eccentric floating rotor screw pumps of the FM series are essentially centrifugal screw pumps. These screw pumps are supplied without a gearbox, meaning that the rotor speed is 750 rpm, 950 rpm or 1450 rpm. Centrifugal screw pumps have all the characteristics of screw pumps (self-priming, no pulsation, etc.), but at the same time have a pressure limit (maximum pressure = 4 bar). These pumps are capable of handling liquids with a maximum viscosity of up to 400 cPs.

The FM series screw pumps can be supplied with an integrated gearbox on the motors.

The eccentric screw pump is the price leader in the price category due to its value.

Distinctive features of the screw eccentric screw pump:

- Compact and versatile design

- Maximum capacity of up to 10 m3/h with a pressure of 4 bar

- The pump can be supplied without an electric motor, with a single-phase motor, with a gear motor.

- High performance combined with efficient design

- Good self-priming ability

- Lightweight and compact

- Low noise level during operation

- Smooth flow

- Extremely easy and inexpensive maintenance (cheap and durable spare parts)

- Various materials for seals, stators and rotors.

- Capacity up to 10,000 litres per hour

- Pressure: up to 4 bar

Options for the screw pump:

- Protection against dry running

- Installing a relief valve

- Various sealing options (single mechanical seal, double mechanical seal, seal with gate fluid, cartridge seal, gland packing).

Areas of application for the screw pump:

- Wastewater (polymers, waste, sludge, flocculants)

- Chemical industry (detergents, varnishes, paints, inks, soaps)

- Construction (cement, concrete)

- Food industry (creams, emulsions, wine, olive oil, etc.)

- Energy (hydrocarbons, coolants and cutting oils, acids)

- Abrasive slurries

- Ideal for OEMs and other manufacturers of complete equipment.

The FM series screw pump is designed for pumping viscous, abrasive and aggressive liquids in industrial processes.

The pump has high performance, pressure up to X bar, and is made of materials resistant to aggressive environments.

You can order an original FM series screw pump from Steiner with an official warranty and delivery throughout Ukraine.

This series is distinguished by its reliability, wear resistance and ability to work with different types of liquids.

Contact our experts, who will help you select a pump according to your technical requirements and the type of liquid.